ABOUT PRODUCT

Cantilever racking is a storage system designed for long, bulky, or irregularly shaped items that are difficult to store on standard pallet racks. It uses horizontal arms extending from vertical columns, creating an open-front design with no vertical obstructions that enables easy loading and unloading with a forklift.

Cantilever storage rack is ideal for storing products including:

Building materials: Lumber, trusses, plasterboard, and steel sheets.

Pipes and tubing: Plumbing pipes, conduit, and steel pipes.

Metal stock: Bars, rods, and beams.

Furniture: Sofas, mattresses, and other large items.

Other long items: Rolls of carpet or large plywood sheets. .

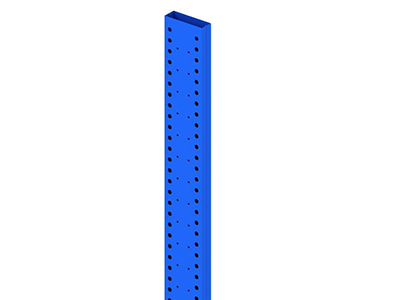

FEATURES OF HEAVY DUTY CANTILEVER RACK

CANTILEVER RACKING SYSTEM SPECIFICATIONS

| Cantilever Racking System | ||

| Style | Single Sided Cantilever / Double Sided Cantilever | |

| Uprights | Double C Channel 250x80x2.0 | |

| Double C Channel 300x90x3.0 | ||

| H Profile Steel 300-400IPE | ||

| Arm Length | Up to 2500mm | |

| Upright Spacing | 750 - 2000mm | |

| Height | Up to 8000mm | |

| Finish | Powder Coated / Galvanized | |

| Options | Mesh Decking / Sheet Decking / Roofing System | |

CANTILEVER STORAGE RACK CONFIGURATIONS

CANTILEVER RACKING APPLICATIONS

HEAVY DUTY CANTILEVER RACK COMPONENTS

Main Components

Accessories

FAQs

General Trade Terms If I want to buy from TOCO

What does TOCO’s after-sales service include?

I cannot find an item on your website, what can I do?